Lisebelisoa tsa elektroniki tsa IC Chips Lipotoloho tse Kopantsoeng tsa IC TPS74701QDRCRQ1 sebaka se le seng.

Litšobotsi tsa Sehlahisoa

| MOFUTA | TLHALOSO |

| Sehlopha | Lipotoloho tse Kopantsoeng (ICs) |

| Mfr | Lisebelisoa tsa Texas |

| Letoto | Likoloi, AEC-Q100 |

| Sephutheloana | Theipi le Reel (TR) Seha Tape (CT) Digi-Reel® |

| Boemo ba Sehlahiswa | E sebetsa |

| Tlhophiso ea Sephetho | E ntle |

| Mofuta oa Sephetho | E ka fetoha |

| Palo ea Batsamaisi | 1 |

| Voltage - Kenyo (Boholo) | 5.5V |

| Voltage - Output (Min/Fixed) | 0.8V |

| Voltage - Output (Boholo) | 3.6V |

| Ho theoha ha Voltage (Boholo) | 1.39V @ 500mA |

| Hajoale - Sephetho | 500mA |

| PSRR | 60dB ~ 30dB (1kHz ~ 300kHz) |

| Laola Likarolo | Noble, Power Good, Soft Start |

| Likarolo tsa Tšireletso | Hajoale, Mocheso o Fetang, Potoloho e Khutšoane, Tlas'a Voltage Lockout (UVLO) |

| Mocheso oa ho sebetsa | -40°C ~ 125°C |

| Mofuta oa ho Beha | Thaba e kaholimo |

| Sephutheloana / Taba | 10-VFDFN Ped e pepesitsoeng |

| Sephutheloana sa Sesebelisoa sa Bafani | 10-VSON (3x3) |

| Nomoro ea Sehlahisoa sa Motheo | TPS74701 |

Kamano pakeng tsa li-wafers le chips

Kakaretso ea li-wafers

Ho utloisisa kamano pakeng tsa li-wafers le chips, se latelang ke kakaretso ea lintlha tsa bohlokoa tsa tsebo ea li-wafer le chip.

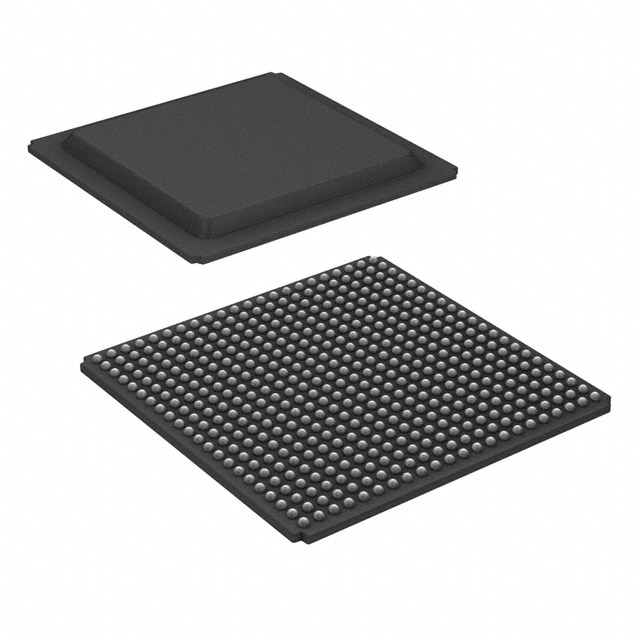

(i) Sephaphatha ke eng

Li-wafers ke li-wafers tsa silicon tse sebelisoang ho hlahisa li-circuits tse kopantsoeng tsa silicon semiconductor, tse bitsoang li-wafers ka lebaka la sebōpeho sa tsona se chitja;li ka sebetsoa ka li-wafers tsa silicon ho theha likarolo tse fapaneng tsa potoloho le ho ba lihlahisoa tse kopaneng tsa potoloho tse nang le mesebetsi e itseng ea motlakase.Lintho tse sebelisoang bakeng sa li-wafers ke silicon, 'me ho na le silicon dioxide e sa cheng holim'a bokaholimo ba lefatše.Silicon dioxide ore e hloekisoa ka har'a libono tsa arc tsa motlakase, e hloekisitsoeng ka hydrochloric acid 'me e hloekisitsoe ho hlahisa polysilicon e hloekileng e nang le bohloeki ba 99.99999999999%.

(ii) Lisebelisuoa tsa motheo tsa li-wafers

Silicon e hloekisoa ho tloha lehlabatheng la quartz 'me li-wafers lia hloekisoa (99.999%) ho tloha ho silicon ea element, e ntan'o etsoa lithupa tsa silicon tse fetohang lisebelisoa tsa quartz semiconductors bakeng sa li-circuits tse kopantsoeng.

(iii) Mokhoa oa ho etsa liphaephe

Li-wafers ke lisebelisoa tsa mantlha tsa ho etsa lichifi tsa semiconductor.Thepa ea bohlokoa ka ho fetisisa e tala bakeng sa li-circuits tse kopantsoeng tsa semiconductor ke silicon mme ka hona e lumellana le li-wafers tsa silicon.

Silicon e fumaneha haholo tlhahong ka sebopeho sa silicates kapa silicon dioxide mafikeng le mahlohlojane.Moetso oa li-wafers tsa silicon o ka akaretsoa ka mehato e meraro ea mantlha: ho hloekisoa le ho hloekisoa ha silicon, kholo ea silicon e le 'ngoe ea kristale, le ho etsa sephaphatha.

Ea pele ke tlhoekiso ea silicon, moo thepa e tala ea lehlabathe le lehlohlojane e kenngoa ka seboping sa motlakase sa arc mocheso o ka bang 2000 ° C le boteng ba mohloli oa khabone.Ka mocheso o phahameng, carbon le silicon dioxide lehlabatheng le lehlohlojaneng li kena karabelo ea lik'hemik'hale (khabone e kopana le oksijene, e siea silicon) ho fumana silicon e hloekileng ka bohloeki ba hoo e ka bang 98%, e tsejoang hape e le silicon ea metallurgical grade, e seng e hloekile ka ho lekaneng bakeng sa lisebelisoa tsa microelectronic hobane thepa ea motlakase ea thepa ea semiconductor e na le kutloelo-bohloko haholo bakeng sa khatello ea litšila.Ka hona silicon ea "metallurgical grade grade" e hloekisoa ka ho eketsehileng: silicon e sithabetseng ea metallurgical e kenngoa ka chlorination reaction ka gaseous hydrogen chloride ho hlahisa silane ea metsi, e ntan'o tšeloa le ho fokotsoa ka lik'hemik'hale ka mokhoa o hlahisang polycrystalline e hloekileng ea 99.9999999999999999999999999999999999999999. %, e fetohang silicon ea boemo ba elektroniki.

E latelang ho tla kholo ea silicon ea monocrystalline, mokhoa o tloaelehileng haholo o bitsoang ho hula ka ho toba (mokhoa oa CZ).Joalokaha ho bontšitsoe setšoantšong se ka tlase, polysilicon e hloekileng haholo e kenngoa ka har'a crucible ea quartz 'me e futhumatsoa ka ho tsoelang pele ka heater ea graphite e pota-potileng ka ntle, e boloka mocheso o ka bang 1400 °C.Hangata khase e ka seboping ha e kenelle, e lumellang polysilicon hore e qhibilihe ntle le ho hlahisa lik'hemik'hale tse sa batleheng.Ho theha likristale tse le 'ngoe, sebopeho sa likristale se boetse se laoloa: crucible e pota-potiloe ka polysilicon e qhibiliha, kristale ea peo e qoelisoa ho eona,' me molamu oa ho taka o fetisetsoa ka lehlakoreng le leng ha butle-butle o o hula ka holimo ho tloha holimo. silicon e qhibiliha.Polysilicon e qhibilihisitsoeng e khomarela botlaaseng ba kristale ea peo 'me e hola ho ea holimo ka lehlakoreng la tlhophiso ea lattice ea kristale ea peo.